Happy Independence to all my brothers and sisters of India. Let us celebrate the spirit of Independence in all splendor, fervor and vibration as we step forward into the 77th year. India to me has always been an emotion and a feeling which one can never really describe in words. Let us make our country India a great and safe nation by following safety at all times.

This will be the 5th year of writing blogs on my web site and I thank each and every reader who read them regularly and have made me improve every time by your critical assessment and by being lavish in your appreciation. I would have not come this far but for all of you. This year I will try to write more and the plan is to write at least 2 blogs a month.

My India Safe India will continue in the next blog as Jaggy and Maggie are busy elsewhere and will be back soon. In this blog I have decided to write about the need, of ERT- EMERGENCY RESPONSE TRAINERS and the impact they create to the society, country and the world in general. I dedicate this blog to my mentors Jagadish Adapa (JAGGY), Late Mr. Jayasheel Adapa and Late Mr. Moeiz Ahmed.

The world today is in a state of VUCA- Volatile, Uncertain, Complex and Ambiguous. The only thing that is certain in this world is SAFETY. Safety can keep us stable, certain, simple and clear in terms of living life happily and to the fullest. But the problem is everyone talks of safety, wants safety but are not sure how to do it and it is where ERT make a big impact. The task of an ERT is to simulate apparently ordinary people to unusual effort. The tough problem is not in identifying winners, it is in making winners out of them. They achieve this objective in 4 ways.

- Explaining the concept.

- Show the trainees how to do it.

- Make them to do it.

- Reconfirm.

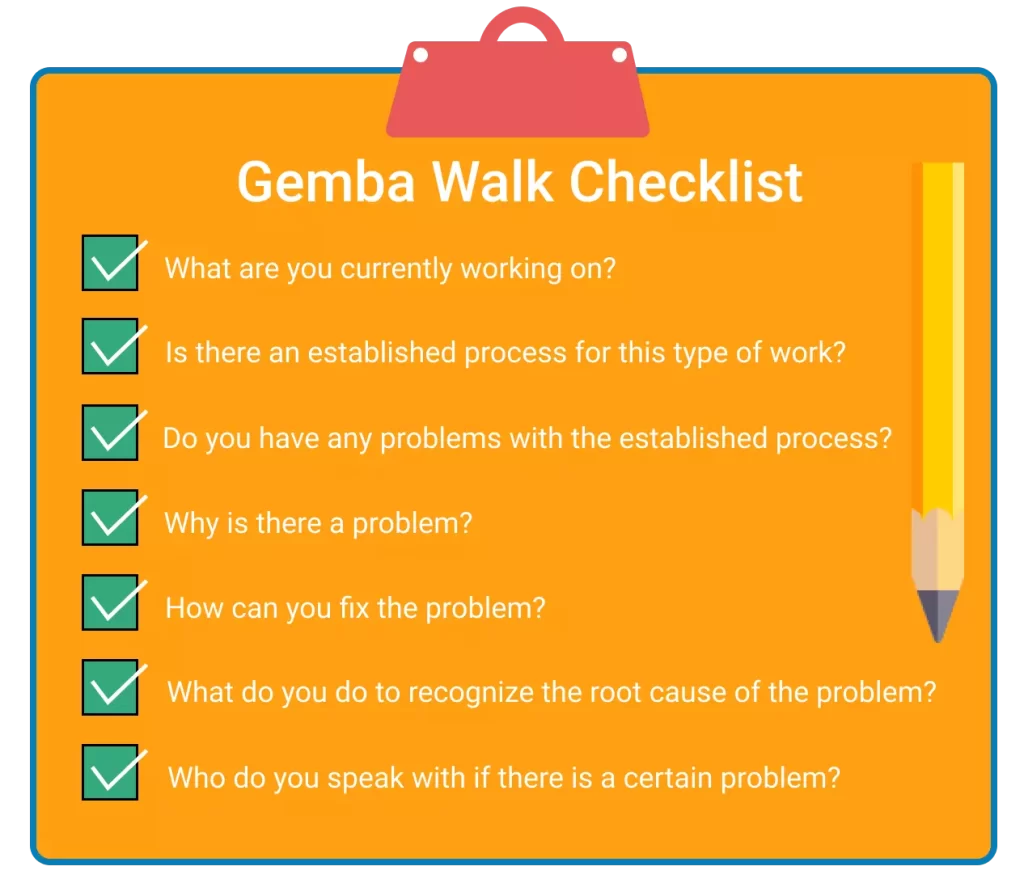

Whether it is using a fire extinguisher, giving CPR, conducting a HIRA, doing a TBT or a Gemba walk the trainer first explains the concept has to be explained in clear and simple terms, to the level of understanding of the trainees. This is done by using audio visual presentations, demonstrations, skits and even an element of drama. Only then the trainees would understand the concept. To meet this objective the trainer must provide information that is current, accurate and specific.

Once the concept is explained the ERT needs to show the trainees how to do it. The pre use inspection, the correct method of operation, precautions to be taken, safety, procedures to be adopted all have to done by the trainers themselves. This can be scary at times when fire is created, rescue on ladders and confined spaces are carried out. Though the demonstrations are done in controlled atmospheres there is always an element of risk involved.

Once the trainers have done their part, the trainees are asked to demonstrate whatever they saw and learnt. Easy to say but, difficult to do as the trainer has to be in complete command. One lapse of concentration and all hell will break loose. The accountability factor is to provide a safe training environment where safety policies and practices are adhered, to fulfil the duties of an incident safety officer and teaching safe operational practices.

Having taught the trainees practically the trainer needs to reconfirm what has been taught. These are done by using methods like repetition, questionnaires, and even assessments. Only then a training can be considered complete.

Apart from imparting knowledge the ERT have to identify gaps in safety and bring it to the notice of the respective organisations, he should be aware of local and international standards and ensure the teaching methods are to the standards. The ERT is also obligated to act in an ethical manner at all times. He should also be a good role model and mentor for his trainees to emulate. The basic of being an ERT is to be a good communicator, present skills and knowledge in a positive way.

Emergency Response Trainers through their teaching create Emergency Responders who go a long way in preventing loss of life and reducing accidents. ERT help the society and the country and are always unsung heroes. They are never in the spotlight but their teaching helps in save lives during any emergency.

As an ERT myself, for the past 17 years and on this day of Indian Independence salute all the trainers all over the world who teach and train in emergency response. May this community keep growing and continue to inspire people to save lives.

Do post your comments as this helps the community of ERT Emergency Response Trainers.

Live Life- Save Life

Seshadri Varadarajan.