Trust all my readers are safe and are on top of the world. The summer had been hot and it was certainly energy sapping. It says that we need to take care of our Planet better than what we are currently doing. Everyone has a role to play and safety professionals a greater role. Let us all together keep this planet of ours safe and sustainable for generations to come.

Continuing their conversation Maggie and Jaggy discuss the Gemba Walk to improve and implement safety in work places. Let us join and listen in.

Maggie: “Hello Jaggy!”

Jaggy: “Hello Maggie! Trust all is well with you.”

Maggie: “Yes Jaggy as usual on Top of the world.”

Jaggy: “Great to hear.”

Maggie: “In our last conversation you were talking about a Gemba walk right.”

Jaggy: “Yes I remember and now you want to know more about it.”

Maggie: “Absolutely!”

Jaggy: “To implement safety as a culture and to ensure all are on the same page certain systems have to be put in place. One such system is a Gemba Walk.”

Maggie: “Can you please explain more clearly?”

Jaggy: “First you need to understand what does Gemba mean?”

Maggie: “So what exactly does it mean?”

Jaggy: “Gemba in Japanese means real place, or the place where value is created. This actually means nothing but a work place be it a shop floor in a factory or any office for that matter.”

Maggie: “So in essence a Gemba walk means walk through the work place.”

Jaggy: “Yes that is correct. Walking through the workplace when everyone is working.”

Maggie: “But how does just walking about a work place or shop floor improve on the safety?”

Jaggy: “Gemba walks are not for safety alone but can be used in a number of ways. The walks when done with a purpose will not only increase productivity but can address a lot of other concerns too.”

Maggie: “Come to the point Jaggy! Let us talk only about Safety.”

Jaggy: “Gemba walks were developed in Toyota keeping view their policy of continuous improvement which in Japanese is called Kaizen.”

Maggie: “Sounds great. Even I have heard of Kaizen.”

Jaggy: “Safety Gemba walks have a 3 elements. 1. Go and See. 2. Ask questions. 3. Show respect.”

Maggie: “Can you be more specific?”

Jaggy: “The first thing any safety official will do is to go and see the place where work is being done. He will see whether the safety policy and compliances are being followed or not. He will observe if there are any violations, minor or major and make a note. 2. He or she will ask questions on the process, compliance and mistakes. Suggestions for improvement are also asked. 3. He or she will show respect by not insulting the employees at that place even if a violation is observed.”

Maggie: “How does this help?”

Jaggy: “This helps in 1. Compliance and standards are being followed. 2. Employees being a part of suggestions and improvements. 3. Correction of unsafe conditions on the spot. 4. Brain storming on how improvements can be made or maintaining the standards at all times. As the employees are involved throughout this helps the managements improve productivity as well as safety.”

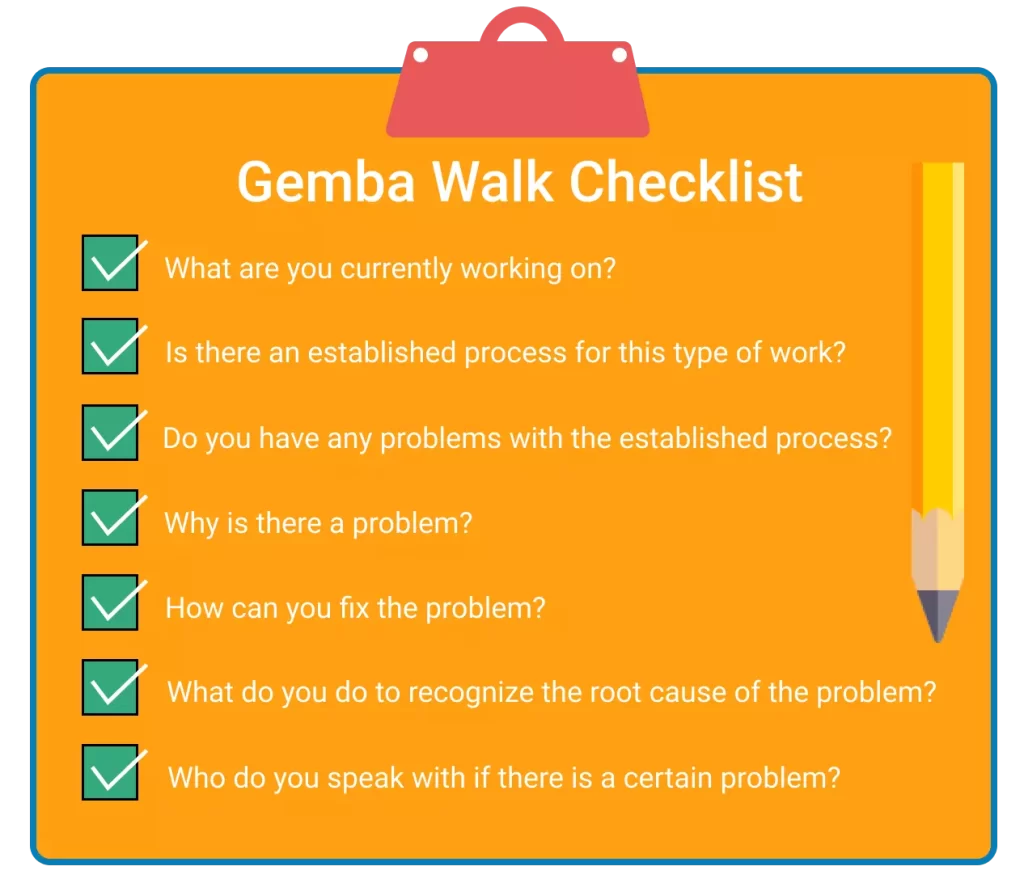

Maggie: “Are there any checklists for the walks?”

Jaggy: “Yes there are checklists which are designed by the managements according to their standards and best work practice.”

Maggie: “What should be the frequency of such Gemba Walks?”

Jaggy: “The frequencies can be fixed. Walks can happen as per a fixed schedule or sometimes even impromptu. These walks are intended to catch people doing the right thing rather than the wrong ones.”

Maggie: “Thanks Jaggy on enlightening me. This was certainly a good discussion. We will catch up on more such safety aspects soon.”

Jaggy: “Sure Maggie stay safe, be safe.”

I would like to all my readers to share in the comments section whether Safety Gemba walks are done at your work place and when would you plan to do the same in your workplace. Please let me know how useful are all my blogs till date. Just stay safe and be safe till my next blog.

LIVE LIFE – SAVE LIFE.

Seshadri Varadarajan.